How to Make Wood Rings from Veneer

How to make wooden rings out of veneer. This is a great project that doesn’t require many tools.

Bentwood Rings Tutorial

In this tutorial video I show how to make wooden rings out of veneer. This is a great project that doesn’t require many tools. In fact all you really need is some super glue, a knife, sandpaper and some tape. Having a lathe or a drill will most definitely help speed up the process. Even if you’re not a woodworker you probably already have all the tools necessary for this quick and simple project. I did find that the first couple rings I made were a bit sloppy but by the time you make your third one you’ll get the hang of it and make some beautiful bentwood rings. I used this technique to make my own wedding rings for myself and my wife. It’s a very rewarding project and suggest you give it a try yourself! If you’re using a drill bit as your template you’ll need to find the equivalent bit size in MM. Ring sizes in MM can be found here.

Here’s What You’ll Need

How to Duplicate a Record

Duplicating a vinyl record using silicon and and resin. A fun lesson in mold making!

Listen to the audio ripped from the duplicated record below.

One of my most fun projects to date! I take a Johnny Cash reissue 7” vinyl record and duplicate it with a silicone rubber mold and liquid plastic. To be quite honest I was surprised on how much detail the mold can handle as the duplicated record played almost perfectly. You can listen to the ripped audio above. There was a few more pops and clicks than the original record and I’m guessing that’s from dust or not cleaning the original enough beforehand. Obviously pirating and duplicating any copyrighted material is prohibited but in the spirit of making and experimentation this was a fun project.

A couple of fun facts about this 7” single: Get Rhythm was the 1956 a-side of this record but it was the b-side that became the huge hit for Johnny Cash. I Walk the Line was the first number one single for Johnny Cash and sold over 2 million copies in it’s original pressing. The copy that I own is a reissue put out by one of my favorite record labels, Third Man Records owned and operated by Jack White.

Original music in the video by Lance Neil Hulsey, Toledo, Ohio

Items Used

Making Acoustic Panels

How to make decorative acoustic panels for your home office or studio.

I record the audio for my podcast and all my voice over work in my office. I recently removed a couch from this room and noticed a significant difference in the audio quality. I was getting a lot more reflection from the walls into my microphone so I’m making these acoustic panels to absorb some of the room sound. I purchased some acoustic foam panels from Amazon and decided to class them up a little bit with a nice wood frame and burlap face. The frame uses a simple picture frame construction with mitered corners reinforced with splines. The face consists of a burlap sack glued to a mitered frame and then screwed on to the base. I purposely exposed the screws and chose to use pocket hole screws for the way they look and how they sit on the surface.

In the video I decided to not voice over the steps but instead talk about how I got to be a YouTuber and all the career changes I’ve made. Making YouTube videos and blogging is a combination of many skills including photography, videography, branding, marketing, audio engineering, graphic design and copy writing.

Please feel free to ask me any questions you may have in the comment section below.

Items and Tools Used

How to Make Wood Rings / Bentwood Rings

Making these wood rings is pretty simple and can be done without many tools.

Making these wood rings is pretty simple and can be done without many tools. Basically we’re going to take some veneer and boil it in water to make it more pliable. We’ll then coil the veneer onto itself and bonding it with CA glue. You’ll find these rings are much stronger than just drilling a hole into wood and cutting the outside shape. That’s because we won’t have any weak points with endgrain. There will be many layers with straight grain laminated with glue which will make them very strong and durable. I’ll also show you how I added these accent lines with a contrasting veneer between 3 coils. Let’s get started.

Items and Supplies Used

How to Make a Coffee Table with Lift Top

How to make a coffee table with a lift top mechanism.

For this easy woodworking project I’m making a coffee table with a lift top mechanism and aluminum legs. The lift-top allows for bringing the table up to perfect height for dining in front of the television or bringing your laptop up to an ergonomic position. This was my first time soldering and brazing aluminum tubing and I’m very happy with the results. The great thing about this brazing technique is there is no need for a welder. All you need is a blow torch and some brazing rods. The lift-up table mechanism from Rockler raises the table 6 1/2 inches and has a forward travel of 17 inches. The top is made mostly from one sheet of 3/4 inch walnut plywood except for the corner accents and the edge banding which is made from solid walnut. I finished the table with one coat of boiled linseed oil to bring out the beauty and 4 coats of polyurethane to add a layer of protection. Links to all the tools and supplies are below along with detailed plans to make this yourself. Purchasing through the provided links helps support the content I provide. If you have any questions or comments please leave them in the comment section below. Learn more about the Bora Saw Plate and Clamp Edge used in the video.

Items Used

Preventing Tear-out When Crosscutting Plywood

Crosscutting plywood with a combination blade almost always results in tear out and I find the easiest way to prevent that is just cover the plywood with painters tape.

Crosscutting plywood with a combination blade almost always results in tear out and I find the easiest way to prevent that is just cover the plywood with painters tape. The tear out tends to happen more so on the bottom side but I like to play it safe and cover both sides before running it through the saw. And that’s how you get a perfect edge with crosscutting veneered plywood on the tablesaw.

DIY Speaker Build

How to make a speaker cabinet from a wire kit.

In this DIY speaker build I’m using 1/2” baltic birch plywood to make a pair of stereo speakers to look like vintage guitar amps. I’m using orange Tolex on the outside with grill cloth for the face and chrome corner protectors on all the edges. The speaker kit comes from Rockler Woodworking and Hardware and includes all the wiring, base ports, speaker and internal dimension plans. If you want to build the exact same speakers as you see in the video, I have plans for sale in my store and there are links down below to all the supplies needed. You can easily change the look of these speakers but choosing a different color Tolex and grill cloth. This was a really fun and pretty simple project to build. Don’t be intimidated with the speaker wiring. If you purchase the kits from Rocker the plans are easy to follow and don’t take any special tools.

Supplies Needed

- 1/2” Baltic Birch Plywood

- Orange Tolex

- Grill Cloth

- Velcro Squares

- 6 1/2” Speaker Kit

- Front Corner Protectors

- Rear Corner Protectors

- Rubber Feet

- Speaker Wire

Tools Needed

Cheap and Easy to Make Planter Boxes

A quick an easy DIY project making window planters.

Earlier this year we had a new front deck installed and we thought it was time to replace all the old planter boxes in the front of the house to go along with the new porch. To make these planters I’m using $6 common board pine from Home Depot. One $6 board is enough for one planter box. This is a real quick and easy project that anybody with a few basic woodworking tools can do.

Products Used

How to Make a Guitar with a CNC Machine

Step by step instructions on how to make a solid body guitar on the CNC using parts from a cheap Epiphone Les Paul.

Step by step instructions on how to make a solid body guitar on the CNC using parts from a cheap Epiphone Les Paul. I purchased my Epiphone Les Paul online for only $120 just to gut it for the electronics, hardware and neck. I used some 8/4 ash for the body and carved out the neck pocket, pickup and electronics cavities on the X-Carve CNC. With an angle grinder and TurboPlane blade I did some final shaping. The pick guard, headstock laminate and truss rod cover was also cut out on the X-Carve CNC using carbide bits from ToolsToday. I’m very please with this guitar build and plan on filming a follow-up video answering your questions as well as discuss what I’d do differently for the next guitar build.

Products Used

Use Flocking to Enhance Your Boxes!

Use flocking on the inside of your drawers to enhance the look and feel of your boxes.

I show you a technique called flocking. This is commonly used in lining the drawers of boxes and cases. It leaves a soft velvety feel and adds a touch of class to your projects. The fibers used in the process are very small and lightweight so I highly suggest proper air filtration and a dusk mask. I flock all the drawers of my bandsaw boxes and sometimes I will flock the cavity the drawer slides into. I really like the look and feel of flocking fibers.

Tool and Supplies Used

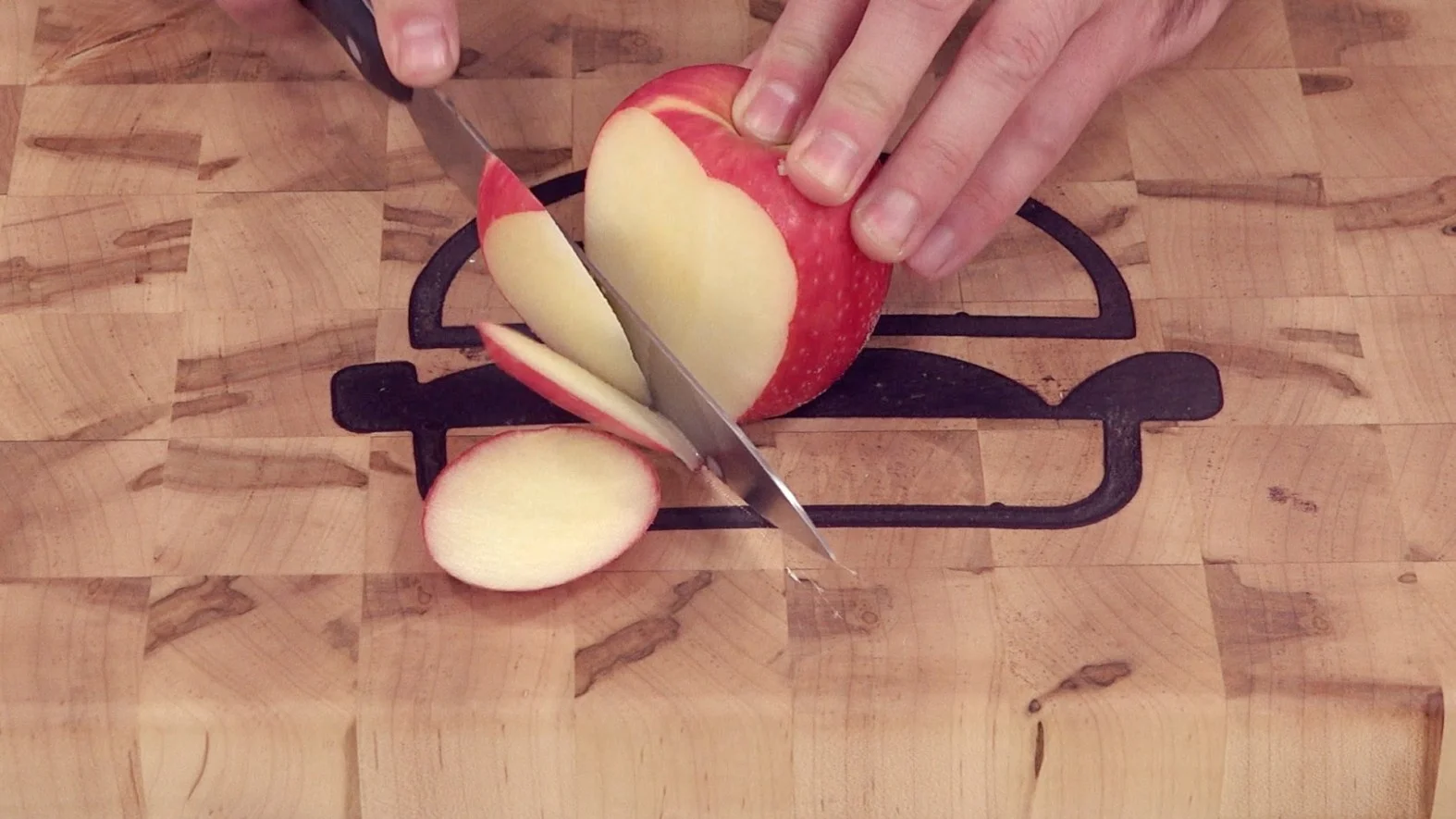

Endgrain Cutting Board with Epoxy Inlay

Endgrain cutting boards are supposed to be easier on your knives than long grain cutting boards because the wood fibers open up and close as the knife passes through.

Endgrain cutting boards are supposed to be easier on your knives than long grain cutting boards because the wood fibers open up and close as the knife passes through. The cutting board we’ll be making is made from soft maple and measures 10.5” x 17” inches. It has some rubber feet and a hamburger inlay that I designed carved out on my X-Carve and filled in with a food safe epoxy. The finish I chose leaves a film on top. If you’re looking for more of a natural finish you could mix up some mineral oil and paraffin wax. Although that type of finish needs to be reapplied more often than this salad bowl finish. In an upcoming video I’m going to make another engrain cutting board but but use a contrasting wood as the inlay instead of epoxy.

Products Used

Super Simple Way on How to Make Paper

How to make homemade paper from recycled materials you can find around the house.

I show you how to make homemade paper from recycled materials you can find around the house. For this easy craft project you will need a paper making deckle (link below), blender, tub of water, sponge, window screen, bath towel, paper towels, an iron and a heat gun. This is a fun craft project that anybody can do. I use my homemade paper to print my photographs on for framing. This adds and extra element of uniqueness to my art.

Links and Products Used

How to Make a 3D Layered Photograph with ArtResin Epoxy

How to make a 3D layered photo using epoxy.

I to show you how to make this 3D layered photograph of my dog. It involves taking 1 image, cutting out the background and making a print from that and another print from the foreground image. In this example I’m making the frame from scratch but you could easily take an existing frame and do this as long as the depth is over 1/2”. That will allow a reservoir for all the epoxy we’re about to use.

I’m using a new product call Art Resin and I’m loving it. Unlike most 2-part epoxies, Art Resin is free of VOCs has no fumes and safe. It’s super clear and easy to use. This is now my go-to for all my kitchen based woodworking projects.

Products Used

Mid Century Modern Cabinet

This mid century modern influenced cabinet is made from baltic birch plywood and walnut plywood.

This mid century modern influenced cabinet is made from baltic birch plywood and walnut plywood. The legs on the mid century cabinet are made from 1 1/2″ thick solid walnut and angled for that classic vintage retro vibe. The drawer is custom fitted to hold k-cup coffee packages along with everything else to make a fine cup of coffee. The two hinged doors open up to reveal an adjustable pinned shelf. Iron on edge banding was applied to the baltic birch to hide the texture of the exposed edges and the outer cabinet was painted white with a standard paint roller. The drawer face and two cabinet doors are make from walnut plywood with solid walnut edge banding to hide the plywood edges. Most of the joinery was made from Festool Domino loose tenons which makes for easy alignment when assembling and provides durable long lasting strength.

Products Used in the Tutorial

X-Carve 3D Carving Overview and CNC Sign Making

Meet the X-Carve the newest 3D carver from Inventables. It’s got 50% less parts than their previous machine which means it takes 50% less time to assemble.

X-Carve 3D Carver Router by Inventables

Meet the X-Carve the newest 3D carver from Inventables. It’s got 50% less parts than their previous machine which means it takes 50% less time to assemble. One power supply to power everything, and a new spindle mount for more rigidity and accuracy. This machine is open source and completely customizable. Today I’m going to show you a technique to make this sign and keeping all the small pieces properly spaced. This technique can be used with any CNC projects that involve small pieces where alignment is key. You can find out more about this machine at Inventables.com

Pallet Wood Project: Key and Coat Rack

A simple coat rack make from free pallet wood!

Pallet Wood Project

The goal of this video is to inspire you to make something. Pallet wood is free and readily available to use and makes for some great woodworking projects. If you leave it rough you’ll get a nice rustic look. This is my first time using pallet wood as well as chalk paint. In this video I’m making a key rack/coat rack/sunglass holder that will be used in the entrance of my house. This is a very basic and simple woodworking project that anybody can do with a few tools. The chalk paint takes that rustic look over-the-top. I’ll add a base coat of gray let that dry and then add some color over top of that. Which we will then distress using sandpaper and a scraper.

- Micro Jig GRR-Ripper

- Folkart Plaid 34168 Home Decor Chalk Paint, 8-Ounce, Castle

- Folkart Plaid 34994 Home Decor Chalk Paint, 8-Ounce, Tuscan Red

- Folkart Plaid 34155 Home Decor Chalk Paint, 8-Ounce, Vintage Mustard

- Folkart Plaid 34169 Home Decor Chalk Paint, 8-Ounce, Rich Black

- Folkart Plaid Sanding Foam Block

- Folkart Plaid Scraper

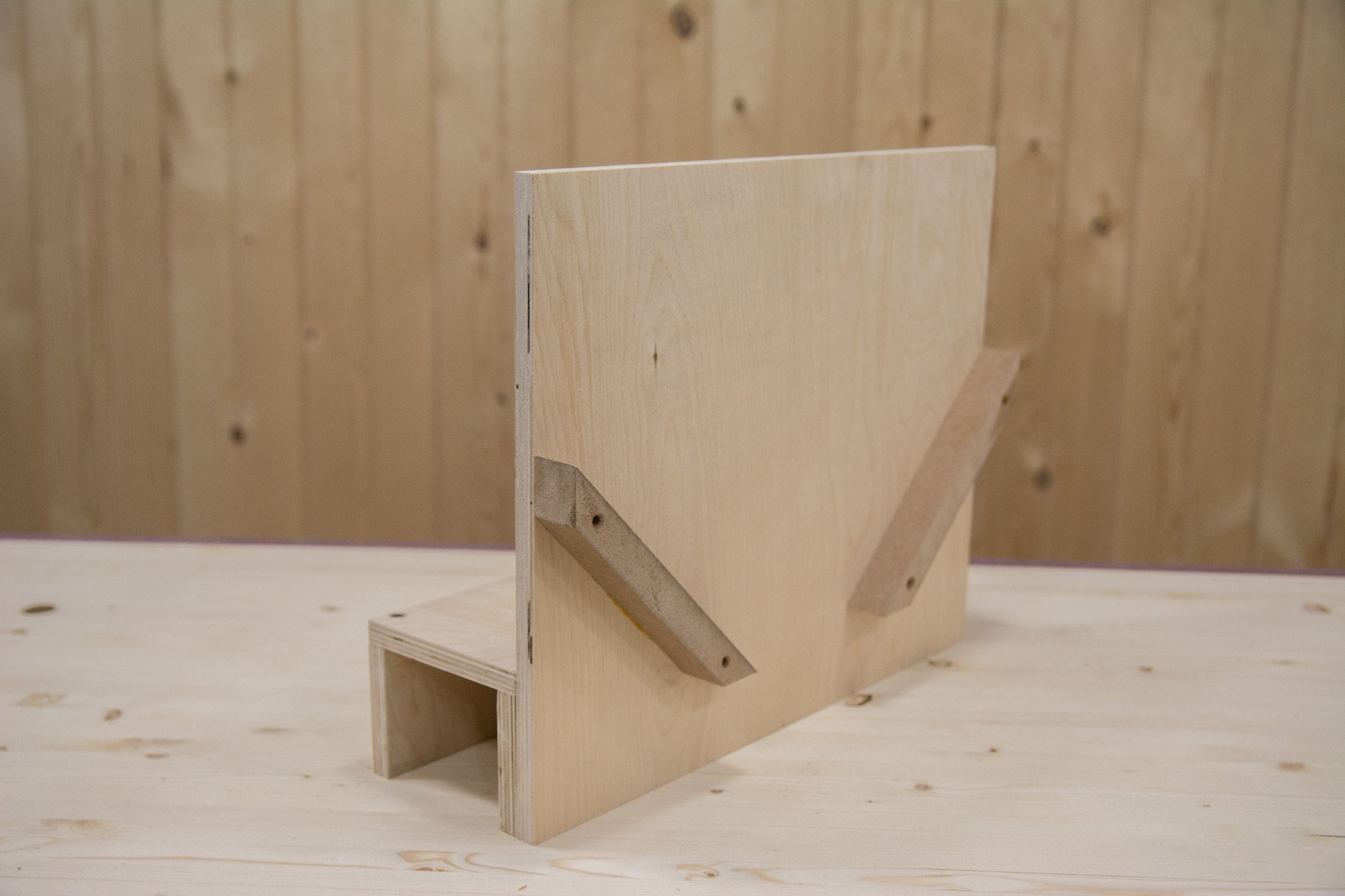

How to Make a Spline Jig for Picture Frames

How to make a spline jig for easily creating mitered corners.

This is the second video in a multi-part series on picture frame making. You can find the other videos in the links down below. This here is a real simple and easy to make jig that rides along your table saw fence and allows you to cut splines in picture frames. Just using glue on mitered corners may seem good enough but over time as the width of the wood expands and contracts with the seasons the joints will eventually break. And that’s why you need splines. Unlike a lot of spline jigs, this rides along the fence and not in the miter slot which means you can place the spline anywhere you want and even cut wider splines by moving the fence and making multiple passes. Setting the blade height is easy since the corner sits just a hair above the table and the two guides easily clear the blade. Let’s get started!

I suggest using a full kerf blade with a flat grind. A thin kerf blade will work just as well and if your blade doesn’t leave a flat bottom cut, don’t worry about it too much. The tiny little gap that it may leave may not even be noticeable and it could always be filled in with sawdust and glue.

How to Make Picture Frames Series

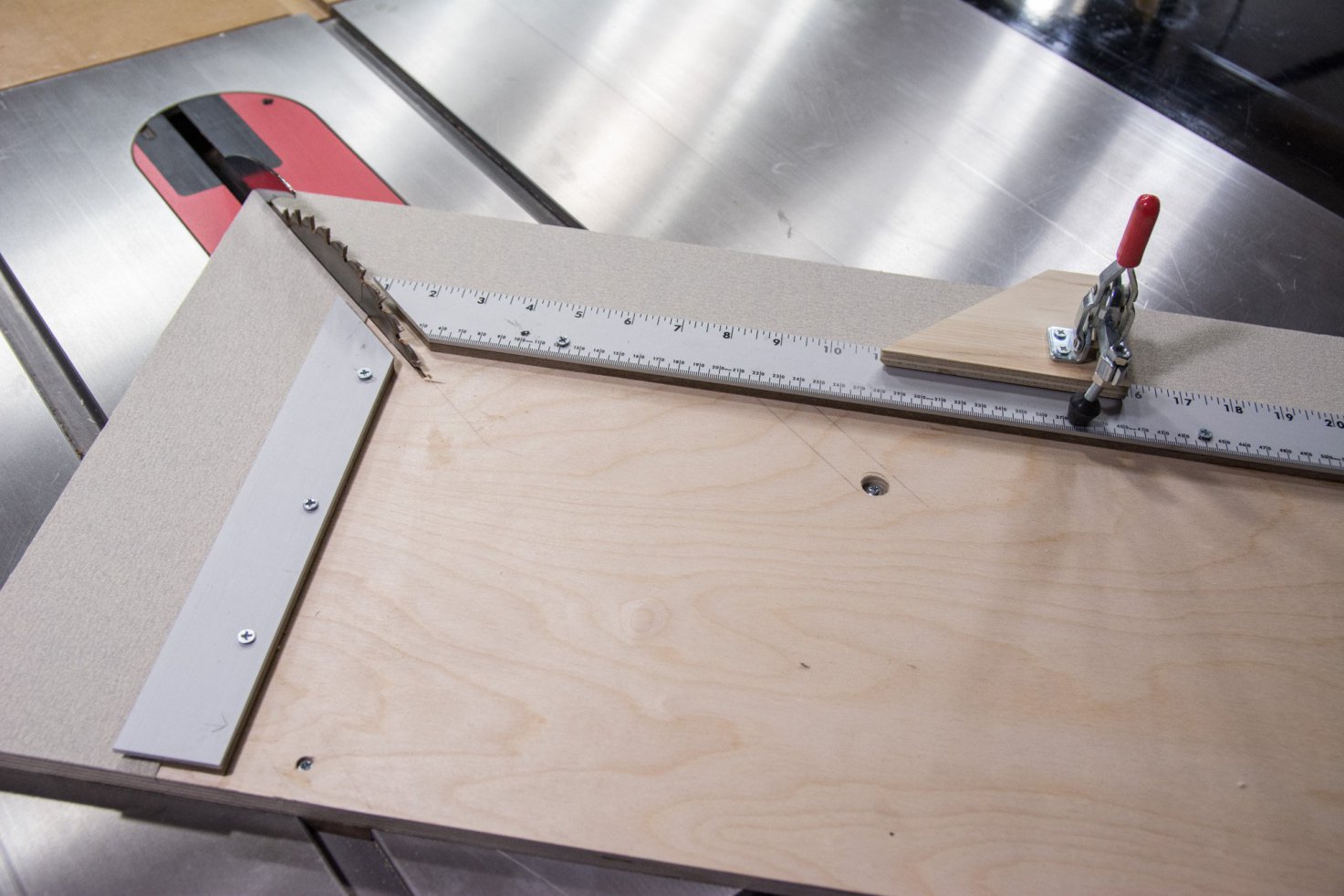

Making The Ultimate Picture Frame Sled

This video gives you an overview on how to make the ultimate picture frame sled.

Here’s What You’ll Need

This is the first video in a multi-part series on picture frame making. This video gives you an overview on how to make the ultimate picture frame sled. In order to make perfect picture frames you need two things… One, the two corner pieces must add up to 90° and the short sides as well as the long sides must be the exact same length. This sled covers both of those issues as well as it allows for larger picture frames than a traditional miter sled stop system. Picture frames are not measured by the inside or outside length but by the rabbit so if your artwork or matte is 5×7 we can set the stop to create a frame for that exact size. To make sure there is no play in our sled we’re using the MicroJig Zero Play Guide bar system that adjusts to fit any table saw. Also, I must give credit to where credit is due. This is a modified and updated sled to one published by Fine Woodworking.

Antique Flip Clock Up-Cycle Project

Taking an old antique flip-clock and upcycling it into a modern design.

Antique flip clock up-cycle woodworking project. I found this old antique flip clock at an antique store for $15. I gutted the clock and rebuilt the outer shell out of walnut using a joinery technique called birdsmouth joinery. Birdsmouth joinery takes a special router bit designed for 8 sided pieces (you can also purchase a router bit for 6 sided pieces). Using some glass I had lying around and a glass cutting tool, cut the octagonal shape. Wedged in behind the glass is metallic card stock cut on a Silhouette Cameo die-cutting machine. The glass and the metallic card stock sits in a groove cut into the inside of the walnut. There is also a rabbet cut in the back to hold the rear piece that is held in by hot glue. The gutted clock fits into the shell snuggly by hot gluing pieces of scrap wood on the inside to hold the mechanical unit. The complete clock was finished with a mixture of boiled linseed oil and polyurethane.

Here’s What You’ll Need

How to Make a Motorized Lazy Susan

How to make this motorized lazy suzan with a rotisserie motor.

I show you how to make this motorized lazy suzan with a rotisserie motor. This is motorized lazy susan is used quite a bit in my videos to highlight and show off my work. When combined with zooms and pans you can create some professional looking video shots without spending a lot money on video gear. What you’ll need is a rotisserie replacement motor found on Amazon and a lazy susan bearing that you can get at any hardware store. I’m using baltic birch plywood for the base construction and veneered plywood for the rotating table. This is an easy project for anybody with a few tools. In this video I’m using a table saw and a band saw but you could easily replace those tools with a hand held jig saw. This motorized lazy susan is great for video work but also makes still photography a more efficient process by placing your subject on the table, turn it on and start shooting photographs without having to stop and rotate the item by hand. This will give you consistent lighting while using the same backdrop and allows you to shoot on a tri-prod.

Here’s What You’ll Need

Woodworking Books

Make Your Own Cutting Boards

15 cutting board projects to make as gifts or sell! Get your signed copy!

The New Bandsaw Box Book

8 bandsaw box projects you can make and sell at craft shows. Signed copies now available!